The best centrifugal process pumps on the market are provided by RINKU ENGINEERS.

What is a Centrifugal Pump?

Centrifugal Pumps are often referred to as Centrifugal Process Pumps or dynamic pressure pumps. It uses centrifugal force to function and is frequently easy to install and maintain.

One of India’s leading makers and manufacturers of Centrifugal Pumps is Rinku Engineers. We manufacture and offer high-quality centrifugal pumps, including horizontal and vertical multistage pumps. We use cutting-edge technologies to satisfy our client’s diverse needs. Our pumps are designed and constructed so that they can be utilized in a variety of industries, including chemical, water and wastewater, sugar, steel, power stations, hydrocarbon handling, irrigation, and water desalination plants.

Centrifugal pumps are used to transport fluids in industrial processes .The Centrifugal Process Pumps Depending on the use, pumps can be vertical or horizontal. They may be powerful centrifugal pumps made to move abrasive or caustic substances. Alternatively, they can be positive displacement pumps.

How Centrifugal Pumps Work?

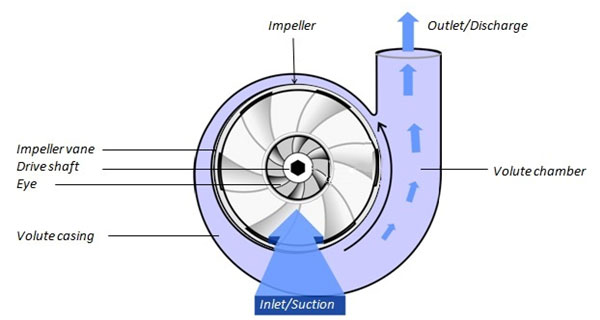

The impeller is the most crucial component of a centrifugal pump. It is made up of several bent vanes.Typically, these are positioned between two discs, which form an enclosed impeller. An open or semi-open impeller supported by a single disc is recommended for fluids containing entrained particulates.

The impeller’s axis, or “eye,” is where fluid enters, and the space between the vanes is where it leaves. On the other side of the eye, the impeller is attached to a motor via a drive shaft and rotates at a high speed (usually 1450-2900 rpm). The fluid is accelerated by the impeller’s spin as it exits the pump casing through the impeller vanes.

The goal of both systems is to transform the fluid flow into a controlled discharge at pressure.

In a volute casing, the offset impeller essentially creates a curved funnel with an increasing cross-sectional area toward the pump output. The fluid pressure rises toward the output as a result of this design .

Advantages and Disadvantages of Centrifugal Process Pumps

Advantages:

Centrifugal pumps offer numerous advantages, such as affordability, minimal maintenance requirements, straightforward design, and high efficiency. Their versatility and importance make them indispensable for many industries, as they can manage diverse fluids and serve various applications.

Disadvantages:

Centrifugal pumps have several drawbacks, including restricted suction lift, limited pressure capacity, and the requirement for a continuous fluid supply. Also they are prone to clogging and harm solid particles in the fluid.

Application of Centrifugal Process Pumps

They are commonly used for pumping water, solvents, organics, oils, acids, bases and any thin liquids in both industrial, agricultural and domestic applications.

| Type of centrifugal pump | Application | Features |

| Canned motor pump | Hydrocarbons, chemicals where any leakage is not permitted | Sealless; impeller directly attached to the motor

Rotor; components in contact with fluids enclosed within. |

| Magnetic drive pump | Sealless; impeller driven by close coupled magnets | |

| Chopper/grinder pump | Waste water in industrial, chemical and food processing/ sewage | Impeller fitted with grinding teeth to chop solids |

| Circulator pump | Heating, ventilation and air conditioning | Inline compact design |

| Multistage pump | High pressure applications | Multiple impellers for increased discharge pressures |

| Cryogenic pump | Liquid natural gas, coolants | Special construction materials to tolerate

low temperature |

| Trash pump | Draining mines, pits, construction sites | Designed to pump water containing solid

debris |

| Slurry pump | Mining, mineral processing, industrial slurries | Designed to handle and withstand highly abrasive slurries |

Technical Details

- Heavy Duty Shaft designed for toughest services.

- Hydraulically and Mechanically Balanced Impeller

- Reduced operating cost

- Versatile shaft seal

- Robust deep groove ball bearings ensure high operating reliability.

- High interchangeability ensures fast delivery and low inventory.

- Environment friendly with Lower noise and vibration levels

- Pump Type – Centrifugal

- Max Flow Rate – 350 M³H

- Max Head – 150 Meter

- Pump Materials – CI, CS, SS304 / 316, SS 304 L

- Max Temp – 300°C

- Max Pressure – 15 kg/cm2

- Operate – AC Electric

Centrifugal Process Pumps Available

- Andhra Pradesh

- Arunachal Pradesh

- Assam

- Bihar

- Chhattisgarh

- Mizoram

- Nagaland

- Odisha

- Goa

- Gujarat (Ahmedabad)

- Haryana

- Himachal Pradesh

- Jharkhand

- Tamil Nadu (Chennai)

- Telangana (Hyderabad)

- Uttarakhand (Dehradun)

- Karnataka

- Kerala

- Madhya Pradesh (MP)

- Maharashtra (Mumbai)

- Meghalaya

- Punjab

- Sikkim

- West Bengal (Kolkata)

- Uttar Pradesh (UP)

Centrifugal Process Pumps | Centrifugal Process Pump | Centrifugal Process Pumps Manufacturer | Industrial Centrifugal Process Pumps | Centrifugal Chemical Pump at Best Price In India | End Suction Centrifugal Process Pump | Centrifugal Chemical Pump at Best Price in India | SS Pumps